Corrosion is one of the most common—and most overlooked—threats to industrial electronics.

Moisture, condensation, and airborne contaminants create electrochemical reactions on circuit boards that degrade metals and compromise functionality.

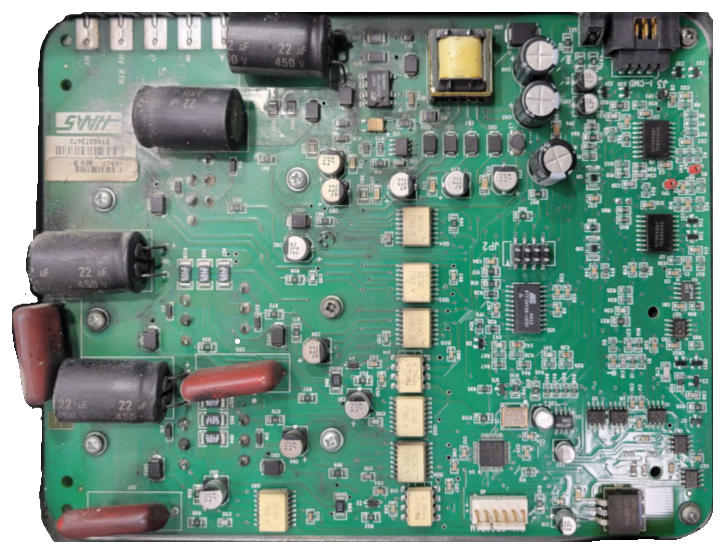

The Case Study: Circuit Board With Early-Stage Corrosion

The board shown below arrived with mild corrosion. At this stage, the damage was localized and had not yet caused total failure. However, if left untreated, corrosion can:

-

Undermine solder joints, leading to intermittent connections

-

Increase resistance across critical traces

-

Cause dendritic growth and shorts between conductors

-

Accelerate failure under thermal cycling

Before: Circuit board showing visible corrosion:

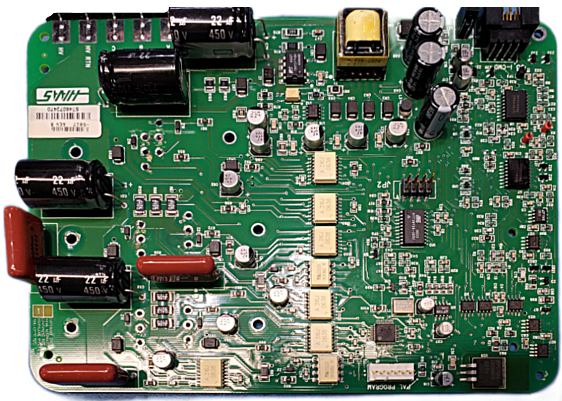

The Repair Process

Our engineers followed a multi-step process to restore this board:

Cleaning & Surface Prep – Contaminants and oxidized material were carefully removed without damaging delicate traces.

Repair & Rework – Solder joints and corroded pathways were restored to ensure electrical integrity; defective components were identified and replaced; suspect components were also replaced preventatively to mitigate future risk. .

Protective Coating – A conformal coating was applied, forming a thin, protective barrier that shields the board from moisture, dust, and other environmental stresses.

After: Circuit board repaired and protected with conformal coating:

Why Conformal Coatings Work: Conformal coatings provide a physical barrier that protects sensitive electronics from corrosion, electrical leakage, and environmental degradation. They are especially valuable for equipment operating in humid, dusty, or fluctuating environments.

The Takeaway: What looks like “minor corrosion” can evolve into catastrophic failure if not addressed. Proactive inspection and protection—like the use of conformal coatings—can extend the operational life of electronics and prevent costly downtime.

Subscribe for More Insights

Subscribe below to receive our updates and ensure you’re always informed about the latest tips and best practices for keeping your operations running smoothly.