|

|

|

Line Isolation Monitors (LIMs)

Line Isolation Monitors (LIMs) are critical safety devices used in hospitals to ensure the safe use of electrical equipment in patient care areas. Their primary function is to monitor the electrical isolation of medical equipment and alert healthcare staff to potential electrical hazards. In addition to isolation monitoring, they detect ground faults and alert or alarm (or both) when a breach is detected.

LIMs play a crucial role in ensuring patient safety and preventing electrical accidents. They prevent electrical shock to both patients and staff; they reduce the risk of equipment damage, reducing downtime and maintenance cost, and help hospitals meet regulatory requirements.:

Popular Brands of LIMs:

- PG LifeLink: Known for its comprehensive medical electrical safety products, including LIMs, PG LifeLink is widely used in hospital settings.

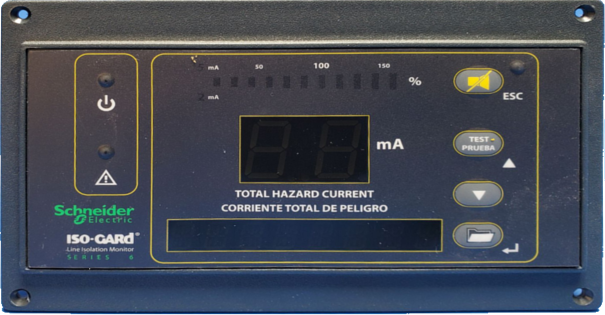

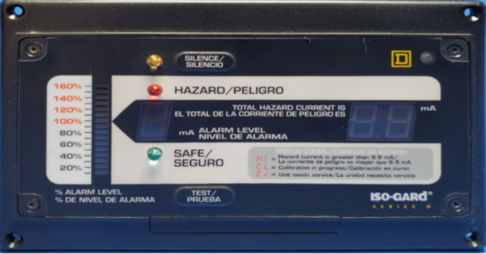

- Iso-Gard (Bender): Bender provides LIMs under its Iso-Gard brand, known for high-quality monitoring devices and systems used in medical environments.

- Isotrol & Isolation Systems Ltd - Canada: Both were acquired by Bender in 1995

- Square D (Schneider Electric): Offers isolation panelboards with integrated LIMs, frequently found in medical facilities.

- Advanced Electrical Systems: Known for supplying isolation power panels and LIMs tailored for healthcare.

- Isolated Power Specialist: Offers an array of LIMs and remote annunciators, including a portable LIM

- Medilec (Clipsal/Schneider Electric): Provides LIMs and isolated power solutions specifically for the medical industry

Failures in an LIM can be caused by a variety of factors, including bad components, wiring errors and/or environmental factors: Common types of failures include false alarms, incorrect readings, and failure to detect hazardous conditions. These failures can result in costly downtime, safety hazards, and damage to equipment. It is important to ensure that the LIM is compatible with the specific electrical system and that it is operated within its specified limits and parameters.

If your unit is showing signs of failures or producing error codes, we can get your equipment back up and running properly. Fill out an RMA or give us a call (716-836-2100), being as specific as possible regarding the issue(s) you are having with the unit.